What is open die forging hammer?

The Open Die Forging Hammer, also known as a free forging hammer, is a type of heavy machinery used in metalworking. This robust piece of equipment functions to manipulate metal into a desired shape by applying gradual pressure, and subsequent deformation, over time. These hammers are engineered to provide immense force, which permits the reshaping and transformation of a variety of metal types.

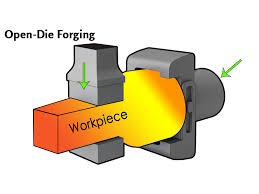

Diving into the mechanics of it, an open die forging hammer comprises a 'die,' which is essentially the surface onto which the metal is placed. This die does not fully enclose the metalwork piece, hence the term 'open die.' When the hammer strikes the metal, which is often heated to increase malleability, the forced deformation results in the desired shape.

Key attributes and advantages of the Open Die Forging Hammer include:

1. Versatility: Capable of crafting parts ranging in size from a few pounds to hundreds of tons.

2. Flexible Design: The open die process allows for a high degree of structural integrity and reduction of inclusions, contributing to the strength of manufactured parts.

3. Economical: This method reduces the need for excessive machining by directly creating shapes close to the final product.

4. Enhanced Durability: Forged pieces are known for their exceptional durability and resistance to impact and wear.

Ideal applications for open die forging hammers

Open Die Forging Hammers, owing to their capacity to forge large and complex shapes, as well as high-strength materials, are ideal for a variety of applications, particularly in heavy industries. Here are some of their most important applications:

1. Aerospace Industry: Used to forge aerospace components such as landing gear, engine shafts or other oversized airplane parts. The high-strength and reliability required in aerospace components make open die forging a suitable production method.

2. Shipbuilding: Maritime applications often require large and durable components. Open die forging is used to produce such parts with a high degree of structural integrity.

3. Energy Industry: In the production of components for power generation equipment like turbines, rotors, and other critical high-stress, high-temperature parts, open die forging is frequently employed.

4. Heavy Equipment Manufacturing: Large machinery for construction, mining, or agriculture often require heavy-duty components. These can be efficiently and effectively produced using open die forging.

5. Oil & Gas Industry: Open die forging produces high-strength components that can withstand the hostile conditions and high pressures of oil and gas extraction and processing.

6. Power Generation: Components like rotors, shafts, and other large-scale parts for power generation equipment such as those in nuclear power plants can be produced through open die forging.

Overall, these hammers are ideally used in situations where strength, reliability, and structural integrity are of utmost importance.

Open Die Forging Hammer, also referred to as free forging hammer, is a type of drop hammer where the dies do not enclose the workpiece, allowing it to flow except where contacted by the dies. This hammer is used in the process of open die forging, in which a metal workpiece is heated and deformed until it reaches a desired shape.

The Open Die Forging Hammer primarily consists of a frame, an anvil, a ram, and a driving device. The workpiece is placed on the anvil of the machine and is hammered by the ram. The driving device controls the motion and power of the ram, allowing precise control over the forging process.

Open Die Forging Hammer is often used in heavy industry such as aerospace, energy, and shipbuilding since it's capable of forging large and complex shapes and high-strength metals. Through the open die forging process, it’s capable of reducing structural inclusions and voids in the metal workpiece, leading to increased mechanical properties and quality of the product.

Overall, the Open Die Forging Hammer is a versatile and robust tool that plays a pivotal role in manufacturing industries. By using this hammer, manufacturers are able to produce robust, high-quality components with improved mechanical properties, structural integrity, and reduced structural defects. It enables us to mold and design complex shapes with ease while maintaining uniformity and strength. This apparatus has transformed the efficiency and quality of forged metal products we see in various industries today.