What is closed die forging hammer?

The Closed Die Forging Hammer, also referred to as an impression-die forging hammer, is a specialized piece of equipment utilized primarily in the metalworking industry. It is known for its durability and high precision, as well as its ability to craft intricate shapes and sizes within a reasonable timeframe at real competitive costs.

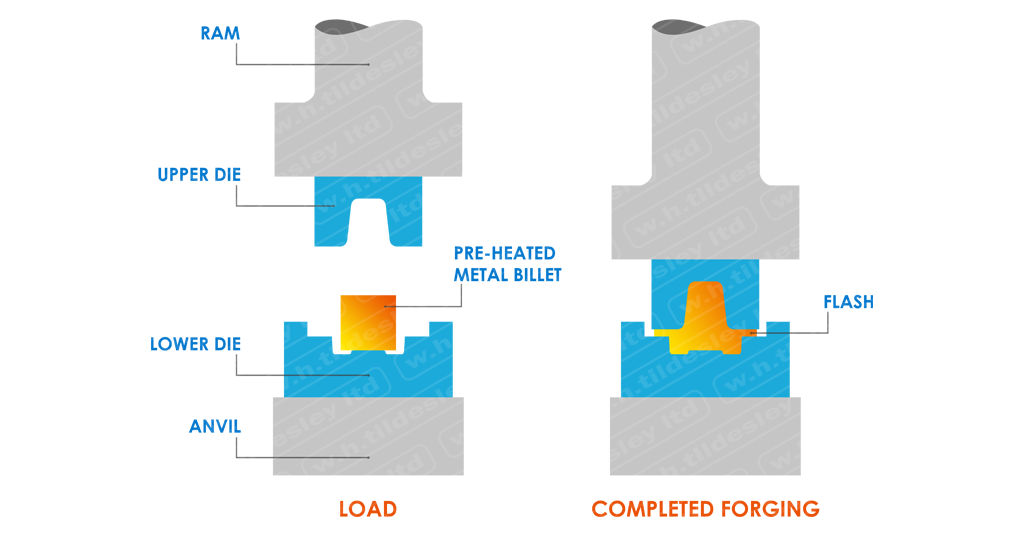

The operational principle of a Closed Die Forging Hammer involves metal being placed in a die resembling a mold, which is attached to the anvil. The hammer, on the other hand, is manipulated to impact force, causing the metal to fill the die cavities and thereby forge the required shape.

Key benefits to highlight include:

1. **Fine Detail**: Using a closed die forging hammer allows for high detail in the finished product. Because the metal is forced into a mold, intricate shapes and designs can be achieved for even the most complex pieces.

2. **Strong Components**: The process results in parts that are characteristically stronger than their casting or machined counterparts. This is due to the metal’s grain structure being aligned to the component's shape during the forging process, which enhances the part's strength and durability.

3. **Material Efficiency**: Unlike some other forms of forging, closed die forging tends to use less starting raw material, and as a result, there is less waste.

4. **Scalability**: The process can be automated, enabling high-volume production runs, and is adaptable to changes in output requirements.

5. **Survival Scenarios**: The possibility of minor core shifts is permissible, which means forgings still survive where castings might fail.

Equipments of this type are commonly used in a wide range of industries, including automotive, aerospace, energy, agriculture, and heavy machinery among others. Thus, the Closed Die Forging Hammer represents a vital technology in modern metal forming manufacturing processes.