Unlocking the Secrets of Ring Rolling Forging

Unlocking the Secrets of Ring Rolling Forging

Introduction

Ring rolling forging is a fascinating and intricate process used to manufacture seamless, circular-wheeled metal parts. Often overshadowed by its more popular manufacturing cousins, like casting or extrusion, this process is a powerhouse in industries like aerospace, automotive, and oil & gas, among others. But what's all the fuss about? This unique forging method provides unmatched strength and reliability, crucial for parts that endure significant stress. Let's unravel the intricacies of ring rolling forging and understand why it's indispensable.

What is Ring Rolling Forging?

Ring Rolling Forging — the Heart of Precision Engineering

Ring rolling forging is a specific type of forging where a thick-walled metal ring is formed into a thinner piece while the diameter increases. This technique achieves improved mechanical properties, with reduced material waste compared to traditional forging methods. Imagine a doughnut being stretched into a wider, flatter form while retaining its circular shape — that's essentially what's happening in this process.

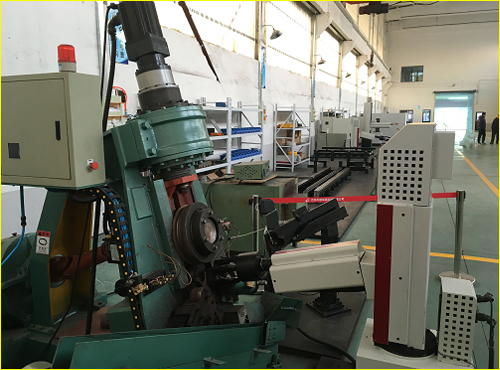

When we mention "ring rolling", we're specifically talking about the transformation of preliminary forged rings into high-precision cylindrical shapes. This process is typically executed on a specialized machine called a ring rolling mill.

The History and Evolution of Ring Rolling Forging

A Glimpse into the Past

Did you know that the art of forging has been around for centuries? That’s right! Initially, techniques involved hammered blades and swords. But industrial evolution saw forging techniques like ring rolling emerge, thanks to the increasing demand for high-strength metals.

The inception of ring rolling can be traced back to the mid-19th century. With the advent of steam engines and railways, there was a growing need for durable wheels, and hence, ring rolling was born. Over the decades, technological advancements improved the process, making it more efficient and precise.

Why Choose Ring Rolling Forging?

The Perks You Can't Ignore

- Superior Strength and Durability: Components produced by ring rolling offer exceptional strength due to the refined grain structure. This makes them ideal for high-stress applications.

- Material Efficiency: This process uses less material compared to conventional forging, translating to cost savings.

- Consistent Quality: With close tolerances and surface finish, these parts meet stringent industry standards without fail.

- Versatility in Materials: From stainless steel to titanium and even exotic alloys, ring rolling accommodates a myriad of materials.

How Does Ring Rolling Forging Work?

Understanding the Mechanics

Ring rolling involves several crucial steps. First, the metal is heated to a precise temperature to enhance malleability. It’s then placed on a mandrel, with axial and radial rolling discs compressing and shaping the material. As the workpiece is rotated, pressure is applied — increasing the ring's diameter and reducing wall thickness uniformly.

Typically, two types of rolling mills are used:

- Radial-Axial Ring Rolling Mill: Designed for producing rings with complex profiles.

- Axial Ring Rolling Mill: Suited for producing flat or slightly profiled rings.

Materials Suitable for Ring Rolling Forging

From Steel to Specialized Alloys

The versatility of ring rolling is partly due to the array of materials that can be successfully forged:

- Carbon and Alloy Steels: Favored for general engineering applications.

- Stainless Steel: Popular in aerospace and medical industries due to corrosion resistance.

- Titanium: Lightweight yet strong, perfect for aircraft components.

- Nickel Alloys: Ideal in high-temperature applications like gas turbines.

| Material | Properties | Typical Applications |

|---|---|---|

| Carbon Steel | Good strength and toughness | Gears, Rings for Bearings |

| Stainless Steel | Corrosion-resistant, durable | Aerospace, Medical Instruments |

| Titanium | High strength-to-weight ratio | Aircraft, Automotive Components |

| Nickel Alloy | Exceptional high temperature resistance | Turbine Components, Chemical tanks |

Ring Rolling Forging Process: A Deep Dive

From Start to Finish

- Pre-Forging: A billet (a piece of metal) is prepared and cut to the desired length.

- Heating: The billet is heated to its recrystallization temperature to ensure malleability.

- Initial Forging: The softened billet is forged into a hollow ring.

- Rolling: Using a ring rolling mill, the ring undergoes radical and axial rolling to achieve the desired dimensions.

- Heat Treatment: To refine the grain structure and enhance mechanical properties, the rolled rings often undergo heat treatment.

- Finishing: Final machining may be conducted to ensure precision in dimensions and surface quality.

Application of Ring Rolling Forging in Industries

The Backbone of Modern Machines

Ring rolling forging is essential in numerous industries, including:

- Aerospace: Producing engine components and structural parts.

- Automotive: Manufacturing transmission components and gears.

- Oil & Gas: Crafting pressure and high-temperature resistance seals.

- Energy Sector: For wind turbines and power generation equipment.

The Advantages of Ring Rolling Forging Over Traditional Forging

Distinct Edges

Why prefer ring rolling forging over traditional methods?

- Enhanced Efficiency: Less waste and a more streamlined process.

- Superior Mechanical Properties: Grain flow is aligned with part contours, improving strength.

- Versatility in Shape and Size: Capable of producing both large rings and smaller, more complex shapes.

Challenges in Ring Rolling Forging

Navigating the Pitfalls

While the process offers numerous advantages, challenges are inherent. These may include:

- Complex Setup: Calibration of rolling mills requires skill and precision.

- Material Limitations: Not all materials respond uniformly to rolling.

- Cost Implications: High initial equipment investment, though offset by material savings.

Innovations and Future Trends in Ring Rolling Forging

Beyond the Conventional

The world of manufacturing is ever-evolving. Innovations in ring rolling include:

- Automation: Integration of AI and IoT for smarter machines.

- New Materials: Research on adapting newer, lightweight alloys.

- Eco-Friendly Practices: Sustainable practices with minimal waste production.

The Environmental Impact of Ring Rolling Forging

An Eco-Conscious Choice

Compared to other manufacturing methods, ring rolling is relatively environmentally friendly. With efficient use of materials and reduced waste, it aligns with sustainable manufacturing goals. Additionally, developments in eco-friendly lubricants and coolants further ensure minimal environmental disruption.

Ring Rolling Forging: A Complex Dance of Precision and Strength

The nuanced finesse of this forging process makes it indispensable for industries that demand precision and reliability. The continuous wave of innovation only propels its capabilities. As industries push the envelope, ring rolling forging remains a steadfast partner, providing unmatched strength and dependability.

FAQs

- What industries use ring rolling forging the most?The aerospace, automotive, oil & gas, and energy sectors frequently use ring rolling forging for manufacturing high-strength metal parts.

- How does ring rolling forging compare with casting?While casting involves pouring liquid metal into a mold, ring rolling forging reshapes solid metal into rings, offering superior mechanical properties due to aligned grain structures.

- Are there size constraints in ring rolling forging?Although incredibly versatile, ring rolling's size limitations are primarily determined by the machining equipment’s capacity and the desired end product specifications.

- Can ring rolling forging handle exotic alloys?Yes, ring rolling can process a variety of alloys, including challenging ones like titanium and nickel alloys, due to its adaptability to various material properties.

- What are common applications of ring rolling in the automotive industry?Ring rolling is often used to produce high-stress components like transmission gears, bearings, and wheel hubs in automotive applications.

- Is ring rolling forging sustainable?Yes, the process is considered sustainable due to its minimal waste production and efficient use of materials.

Conclusion

Ring rolling forging, while a specialized niche in manufacturing, holds a pivotal role across industries that prioritize strength, precision, and reliability. Emphasizing efficiency and versatility, it transcends limitations of traditional forging methods. As technology advances, ring rolling continues to adapt and evolve, ensuring a lasting impact on manufacturing landscapes globally. By aligning with sustainable practices and future innovations, ring rolling forging is set to shape the future of forged components.