Understanding Ring Rolling Machines: Types, Applications, and Benefits

Introduction to Ring Rolling

Ring rolling is a sophisticated metal forming process that begins with a circular preform, often referred to as a 'doughnut.' This preform is heated and placed between rollers, which compress it radially. As the rollers apply pressure, the ring's diameter increases while maintaining its volume, resulting in a seamless ring with enhanced mechanical properties. This method is particularly effective in producing rings with uniform grain structures, which are crucial for applications demanding high strength and durability.

The ring rolling process is indispensable in industries such as aerospace, automotive, and energy, where high-quality, durable components are essential. In the automotive sector, for instance, rolled rings are integral to the structural integrity of vehicles, providing components like bearings and gears with superior strength and resistance to wear. Similarly, in the aerospace industry, the ability of rolled rings to withstand extreme conditions makes them ideal for critical applications such as aircraft engines and turbine components.

One of the key advantages of ring rolling is the enhancement of the material's grain structure. The process aligns the grains in a circular pattern, which significantly boosts the ring's strength and uniformity. This structural integrity is maintained even under high-temperature conditions, making rolled rings more robust than those produced by other methods. This characteristic is particularly beneficial in applications where components are subjected to extreme stress and temperature fluctuations.

Ring rolling can be executed as either hot or cold rolling, depending on the material and the desired properties of the final product. Hot rolling involves heating the metal above its recrystallization temperature, which allows for easier shaping and results in a refined grain structure. Cold rolling, on the other hand, is performed at ambient temperatures and is used when precision and surface finish are critical. Both methods can produce rings in various configurations, from flat, washer-like parts to tall, cylindrical shapes, catering to diverse industrial needs.

Types of Ring Rolling Machines

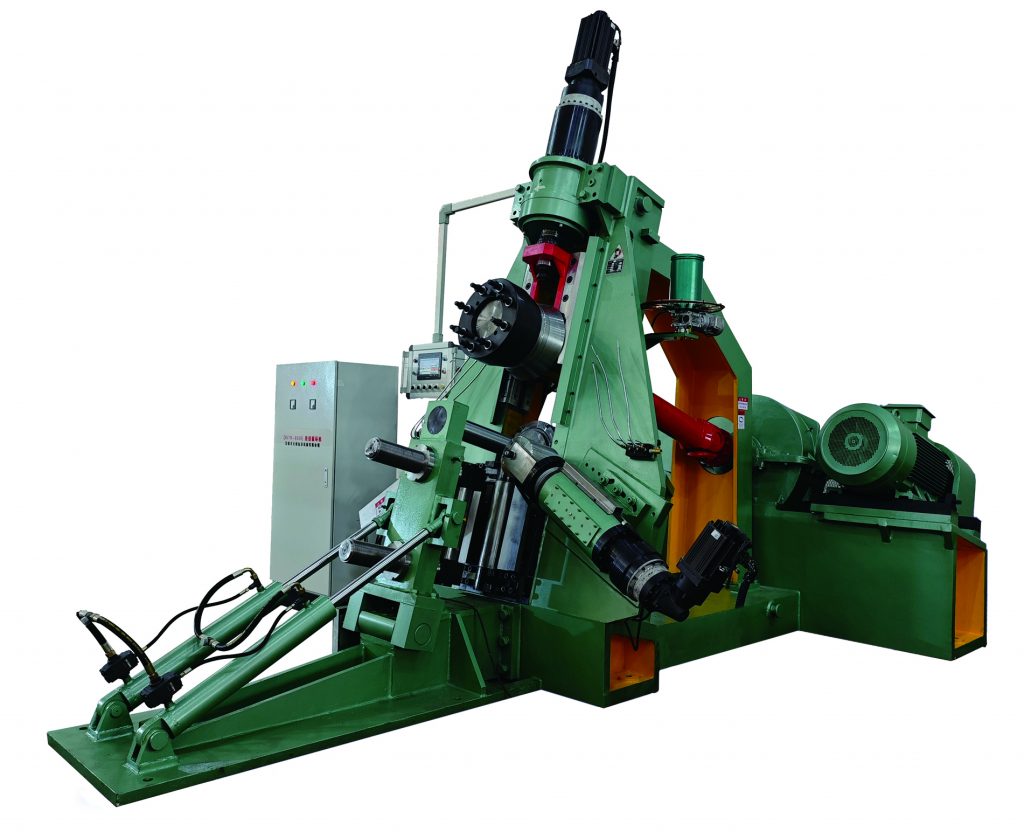

Radial-axial ring rolling machines are engineered to provide exceptional precision in the production of large-diameter rings. By integrating both radial and axial rolls, these machines ensure meticulous control over the ring's dimensions, resulting in a uniform and high-quality product. This dual-roll system is particularly advantageous for applications requiring high precision, such as in the aerospace and energy sectors, where the integrity and exactness of the rings are paramount.

Radial ring rolling machines, equipped solely with radial rolls, are optimized for the production of smaller rings where width precision is less critical. These machines are ideal for applications that do not demand stringent control over the ring's width, making them suitable for industries such as automotive and machinery manufacturing. Their simpler design compared to radial-axial machines allows for cost-effective production while maintaining adequate quality for less demanding applications.

Vertical and horizontal ring rolling machines offer distinct advantages based on their orientation. Vertical machines, often used for smaller operations, provide ease of access and control, while horizontal machines are preferred for larger rings due to their stability and ability to handle greater forces. The choice between vertical and horizontal configurations depends on the specific requirements of the production process, including the size and shape of the rings being manufactured.

Advanced ring rolling machines are equipped with state-of-the-art features such as automated controls, digital readouts, and programmable settings. These enhancements significantly boost operational efficiency and precision, allowing for consistent production quality. Automation reduces human error and material waste, making these machines an attractive option for high-volume production environments. Industries that demand high precision and efficiency, such as aerospace and automotive, benefit greatly from these technological advancements.

Applications in Industries

In the aerospace industry, ring rolling machines are indispensable for producing turbine disks and bearing rings, which are critical components requiring exceptional strength and precision. The seamless nature of the rings produced ensures uniformity and reliability, essential for the high-stress environments of aerospace applications. The process allows for optimal orientation of metal fibers, enhancing the mechanical properties of the components, which is crucial for the safety and performance of aircraft.

In the automotive sector, ring rolling machines are pivotal in manufacturing gear rings, wheel hubs, and bearing races. These components are vital for vehicle performance and safety, as they endure significant wear and tear. The process of ring rolling ensures that these parts are not only lightweight but also capable of withstanding high torque and pressure, making them superior to other manufacturing methods in terms of durability and efficiency.

In the oil and gas industry, ring rolling machines are crucial for creating flanges, valve bodies, and pressure vessel components. These components must withstand extreme pressures and corrosive environments, making the strength and seamless nature of rolled rings particularly advantageous. The ability to produce components with precise tolerances and superior mechanical properties ensures the integrity and safety of oil and gas infrastructure.

In the energy sector, ring rolling machines contribute significantly to renewable energy solutions by manufacturing components like slewing rings and gear rings for wind turbines. These components must endure harsh environmental conditions and mechanical stresses, making the durability and precision of rolled rings essential. The seamless construction and material efficiency of the ring rolling process support the development of sustainable energy technologies.

Benefits of Ring Rolling Process

The ring rolling process is renowned for its cost-effectiveness, primarily due to its ability to minimize material waste. By utilizing pre-cut blanks and generating minimal scrap, this method significantly reduces production costs. Unlike traditional machining, which often involves cutting away excess material, ring rolling forms the ring to its near-final shape, ensuring optimal use of raw materials. This efficiency not only lowers expenses but also contributes to environmental sustainability by reducing waste.

Ring rolling significantly enhances the strength and durability of components by refining the material's grain structure. This process aligns the grains circumferentially, which not only increases the component's strength but also its resistance to fatigue and impact. Such structural integrity is crucial for applications subjected to high stress and temperature fluctuations, ensuring that the components maintain their performance and longevity even under demanding conditions.

The versatility of ring rolling machines is one of their most significant advantages. They can handle a wide array of materials, including alloys, stainless steel, and aerospace metals, making them suitable for diverse industrial applications. This adaptability extends to the sizes and shapes of the rings produced, allowing manufacturers to customize components to meet specific requirements. Such flexibility is invaluable in industries like automotive, aerospace, and energy, where precise specifications are crucial.

Precision and uniformity are hallmarks of the ring rolling process, which consistently produces rings with exact dimensions and superior surface quality. This high level of precision is achieved through controlled deformation and meticulous process parameters, ensuring that each ring meets stringent quality standards. Such accuracy is essential in applications where dimensional consistency is critical, such as in the production of bearings, gears, and other mechanical components.

Leading Manufacturers

Wuxi Daqiao Bearing Machinery Co., Ltd. is renowned for its D51 ring rolling machine, a versatile tool in the manufacturing of bearing races and automotive components. This machine excels in transforming diverse materials such as gear blanks and pipe flanges into precise circular shapes, enhancing material utilization and reducing waste. With over 20 years of experience, Wuxi Daqiao has established itself as a leader in the industry, supported by a skilled technical team and state-of-the-art equipment. www.ringrollingmachine.com