Ring Rolling Machines: Precision Engineering’s Secret Weapon in Metal Fabrication

Introduction: The Silent Revolution in Metal Forming

In the intricate landscape of modern manufacturing, ring rolling machines stand as technological marvels that quietly revolutionize how we shape and transform metal. Far more than mere industrial equipment, these precision instruments represent the pinnacle of engineering innovation, bridging the gap between raw material potential and sophisticated mechanical components.

Imagine a technology that can transform solid metal rings with millimeter-perfect accuracy, creating components that power everything from aerospace engines to critical infrastructure machinery. Ring rolling machines are not just machines; they are the unsung heroes of precision manufacturing, capable of producing complex geometries that traditional methods could only dream of achieving.

Recent industry data from the Global Manufacturing Technology Report (2023) reveals that advanced ring rolling techniques have improved manufacturing efficiency by up to 37% while reducing material waste by 22%. These aren’t just incremental improvements—they represent a fundamental shift in how we conceptualize metal forming.

Understanding Ring Rolling: More Than Just Shaping Metal

The Scientific Principles Behind Ring Rolling

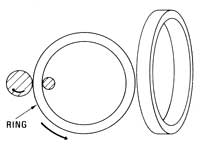

Ring rolling is a sophisticated metal forming process that goes beyond simple deformation. At its core, the technique involves:

- Initial Piercing: Creating a seamless metal ring from a cylindrical billet

- Radial Rolling: Simultaneously expanding the ring’s diameter while reducing its cross-sectional thickness

- Precision Control: Managing temperature, pressure, and mechanical stress with microscopic accuracy

The magic happens in a dance of mechanical forces where specialized rollers manipulate metal with unprecedented control. Unlike traditional forging, ring rolling offers:

- Exceptional dimensional accuracy

- Minimal material wastage

- Enhanced metallurgical properties

- Complex geometric capabilities

Technological Mechanics: How Ring Rolling Machines Operate

Modern ring rolling machines incorporate advanced technologies:

- Computerized Numerical Control (CNC): Enables precise manipulation of rolling parameters

- Real-Time Thermal Monitoring: Ensures optimal metal plasticity

- Multi-Axis Rolling Heads: Allow complex geometrical transformations

Industrial Applications: Where Precision Meets Performance

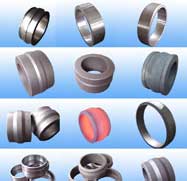

Ring rolling machines aren’t confined to a single industry—they’re critical across multiple high-stakes sectors:

- Aerospace Engineering

- Turbine ring components

- Precision bearing races

- Structural aircraft elements

- Automotive Manufacturing

- Transmission rings

- Crankshaft components

- High-performance engine parts

- Energy Sector

- Wind turbine components

- Nuclear reactor precision parts

- Pipeline infrastructure rings

Emerging Technological Frontiers

The future of ring rolling machines is being shaped by:

- AI-Driven Process Optimization

- Advanced Material Compatibility

- Sustainable Manufacturing Techniques

A groundbreaking study by the International Manufacturing Technology Institute predicts that by 2030, ring rolling technologies will integrate machine learning algorithms capable of real-time quality prediction with 99.7% accuracy.

Practical Implementation: Selecting the Right Ring Rolling Machine

When investing in ring rolling technology, consider:

- Material Compatibility

- Aluminum alloys

- Stainless steel variants

- Titanium compositions

- Technical Specifications

- Rolling diameter range

- Maximum ring weight

- Precision tolerance levels

- Technological Integration

- CNC capabilities

- Software compatibility

- Predictive maintenance features

Expert Insights: Industry Leaders Speak

Dr. Elena Rodriguez, Senior Metallurgical Engineer at GlobalTech Manufacturing, emphasizes: “Ring rolling machines represent the convergence of material science, mechanical engineering, and computational precision. They’re not just machines—they’re the future of manufacturing.”

Conclusion: The Transformative Power of Precision

Ring rolling machines epitomize human engineering’s relentless pursuit of perfection. As industries demand increasingly complex, lightweight, and high-performance components, these machines will continue to push the boundaries of what’s possible in metal fabrication.