Mastering Precision and Efficiency: Unveiling the Secrets of Ring Rolling Mills

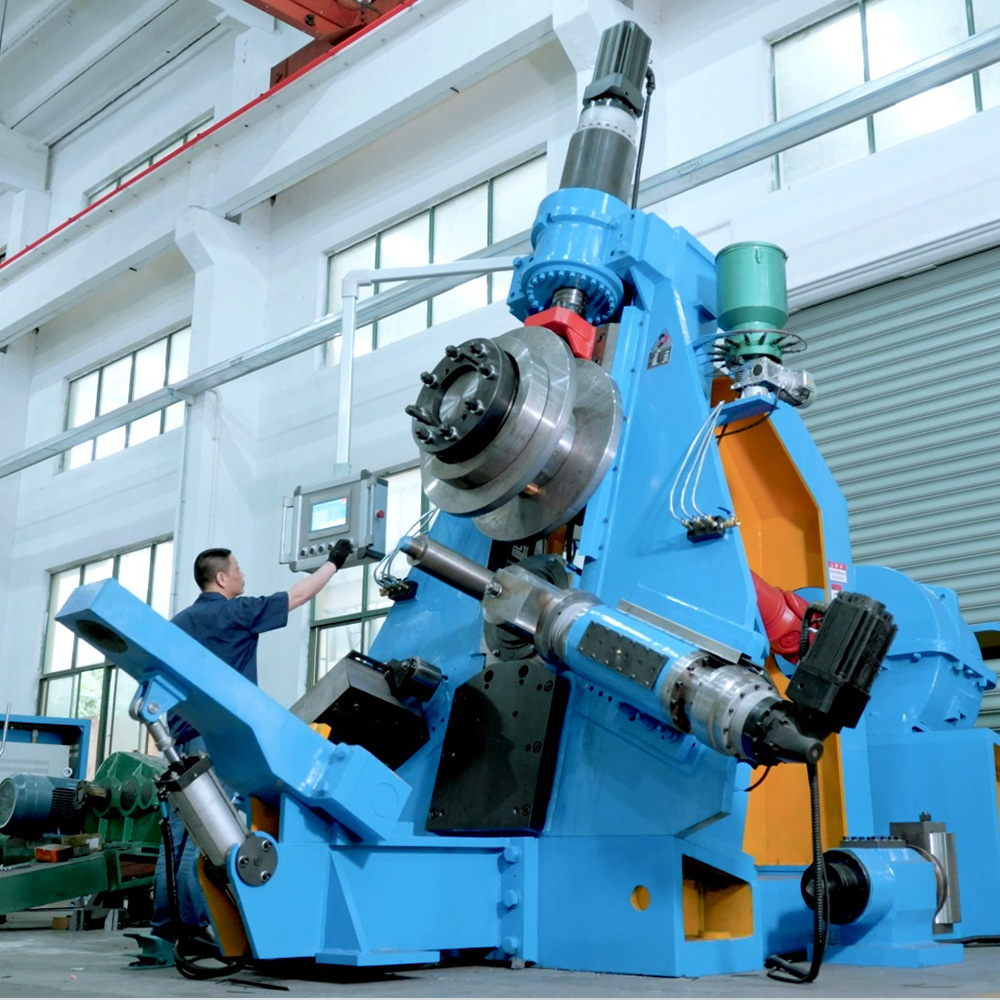

The Ring Rolling Mill is a highly precise and efficient mechanical equipment widely used in the manufacturing industry, particularly in the production of metal products. This article will provide a detailed introduction to the performance, principles, and applications of the Ring Rolling Mill, helping to understand the advantages of this complex equipment.

Performance:

The Ring Rolling Mill is favored by the manufacturing industry for its superior performance and reliability. Firstly, it can produce large and precise ring-shaped products to meet diverse production needs. Secondly, these machines employ advanced components and technologies to ensure long-term operation and consistent performance. The Ring Rolling Mill is also praised for its low energy consumption, resource savings, and reduced production costs.

Principles:

The working principle of the Ring Rolling Mill is based on a process that combines pressure and heat to shape and modify metal materials. By preheating the metal and placing it under specific dies, it is then compressed into the desired shape using a large press. During this process, the particle structure of the metal is rearranged, resulting in a uniform and precise ring-shaped form.

Applications:

The Ring Rolling Mill finds wide applications in various industries, including aerospace, defense, automotive, energy, and heavy industries. In the aerospace sector, the Ring Rolling Mill is used to manufacture critical components of aircraft, such as engine fan blades. In the automotive manufacturing field, they are commonly used for producing bearings and gears. Additionally, this machine plays a significant role in the construction industry for manufacturing large support structures like bridges and towers.

Wuxi Daqiao Ring Rolling Mill is a powerful and precise equipment designed for efficient production of various sizes and types of metal rings. Its versatile performance and widespread applications make it an indispensable tool in the manufacturing industry, driving the development of modern manufacturing.